We all have that one beer; our so-called “Ah-ha!” moment. I remember mine vividly. It was a Russian imperial stout, much like our very own Wicked Dark. Everything about that beer was pleasing to me: the jet-black color, the inch-and-a-half of brown-tinted foam on top, a warm alcohol sensation. It was rich with complex coffee, chocolate, and raisin flavors, and left delectable roast notes in the aftertaste. I wanted more not only more of that stout, but more craft beer in general.

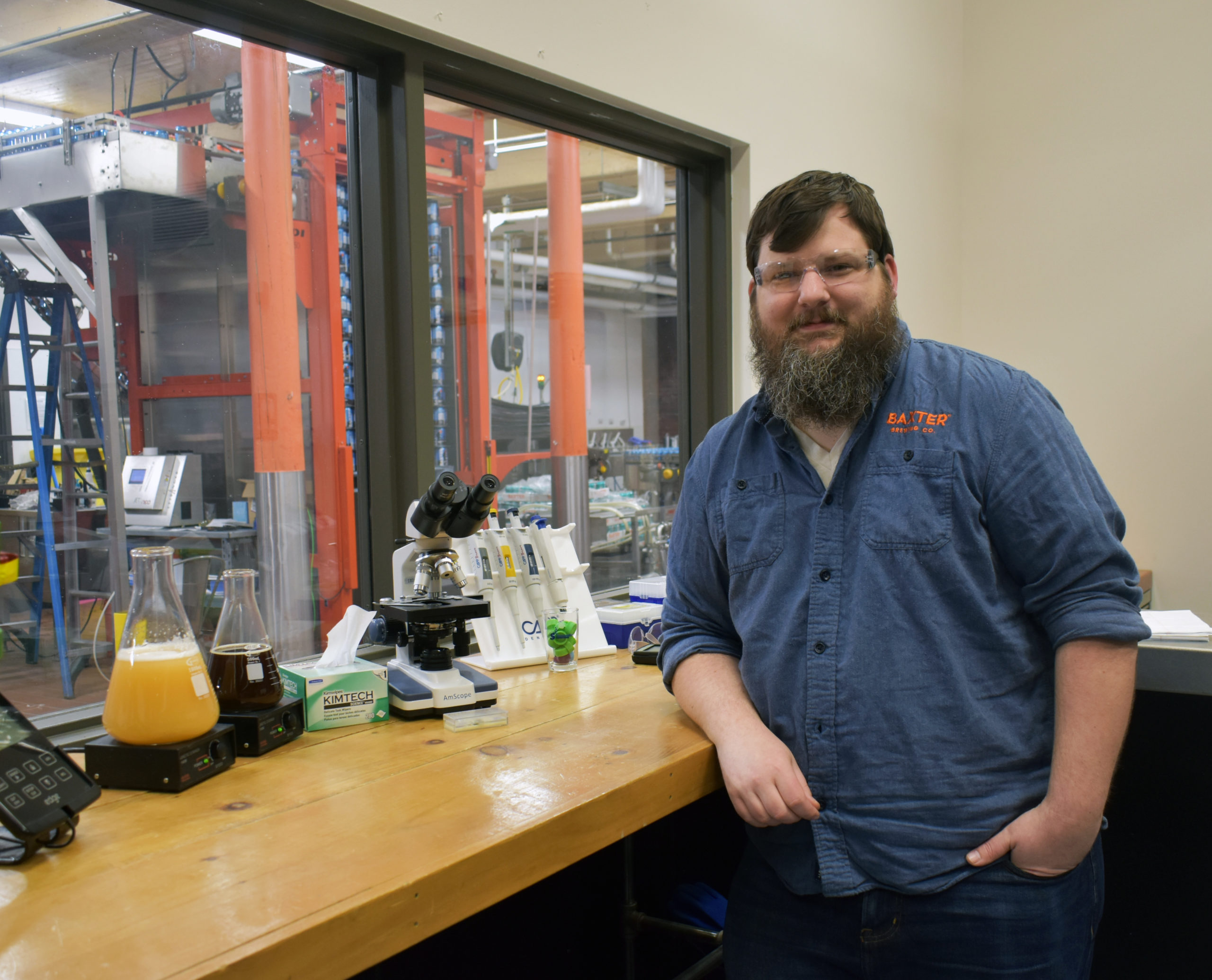

Fast-forward 15 years and I am still on the hunt, but now as the Quality Director at Baxter Brewing Company. I am not just looking for the next great beer, but for the essence of what makes each of our brands unique.

I know what you are probably thinking: “Quality Director at a craft brewery, what a sweet gig; he just drinks beer all day!” Yes, there is beer drinking involved, but there is more to the gig than drinking pint after pint. One of my core responsibilities here at Baxter is the measurement of our product. Sometimes that measurement requires drinking beer. This is where our sensory program comes in. We use human senses (sight, smell, taste, touch, and hearing) to quantify thousands of different flavor molecules that contribute to the essence of each brand. Internally we call the essence of each brand “true-to-target.” Being able to identify a true-to-target profile and to test future brews against it is the goal of our sensory program. Once we set a true-to-target profile, we have a baseline to use when monitoring the condition of our beer, allowing process improvements.

In order to set true-to-target profiles for each brand we need a lot of people to drink our beer. We call this group of people our tasting panel. Every Baxter employee has the opportunity to join our tasting panel and hone their pallet. As fun as it is being part of the panel at Baxter, it is serious work. Each panel member goes through our sensory training program and must practice by participating in at least one tasting per week. Our panel sessions are much different than drinking a beer in The Pub. Panelists are asked to be mindful of what they are drinking and must fill out a data collection form that asks of specific visual, aromatic and flavor attributes. All this data is collected on a sensory analysis application called Draught Lab Pro.

Typically, we hold sensory panel in our brewery lab where we can control the environment. We reduce distractions like the aroma of boiling wort or bacon cheeseburgers being cooked in the kitchen next door. During the COVID-19 pandemic holding large sessions in the lab has not been possible, so we have adapted. We now send sensory beer kits home with our panelists for “Sensory Homework.” Tasters fill out their data collection forms while responsibly distanced from each other in their own home.

After repeated tastings with our large panel I then synthesize the data and group similar attributes. For example, after five tasting panels of Stowaway IPA the three most common attributes cited were grapefruit, orange, and pine. These qualities make up the essence of Stowaway, what we call true-to-target. Therefore, the true-to-target attributes we are looking for in subsequent Stowaway brews are grapefruit, orange, and pine. This true-to-target concept is very important to our quality control and quality assurance program. It sets a baseline for us to compare batches in the future, make decisions about the condition of our brands, and ensure only the best beer makes it to you, the Baxter Brewing fan.

Cheers,

Merritt Waldron – Quality Director

Merritt is the author of the book Quality Labs for Small Brewers available from Brewers Publications on August 3rd 2020

Link URL: https://www.brewerspublications.com/products/quality-labs-for-small-brewers